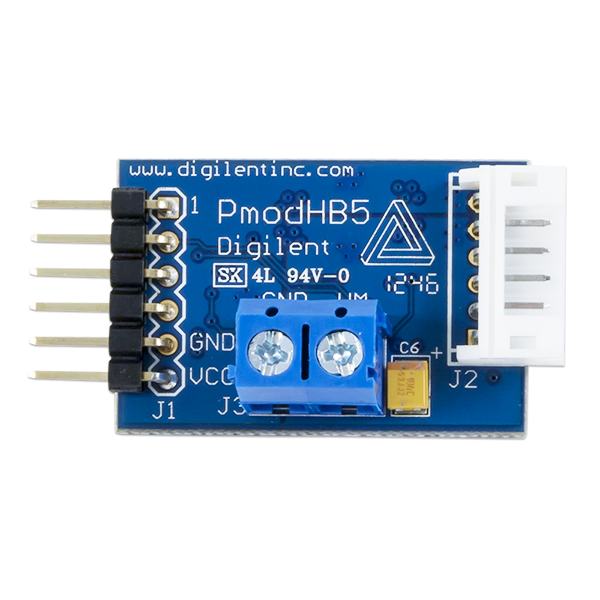

How to Use PmodHB5_Driver: Examples, Pinouts, and Specs

Design with PmodHB5_Driver in Cirkit Designer

Design with PmodHB5_Driver in Cirkit DesignerIntroduction

The PmodHB5 Driver is a versatile motor driver module capable of driving DC motors with an output current of up to 5A. It is designed to be interfaced with microcontrollers such as the Arduino UNO and can be controlled using digital PWM (Pulse Width Modulation) signals. This module is ideal for applications requiring precise motor speed and direction control, such as robotics, automated machinery, and educational projects.

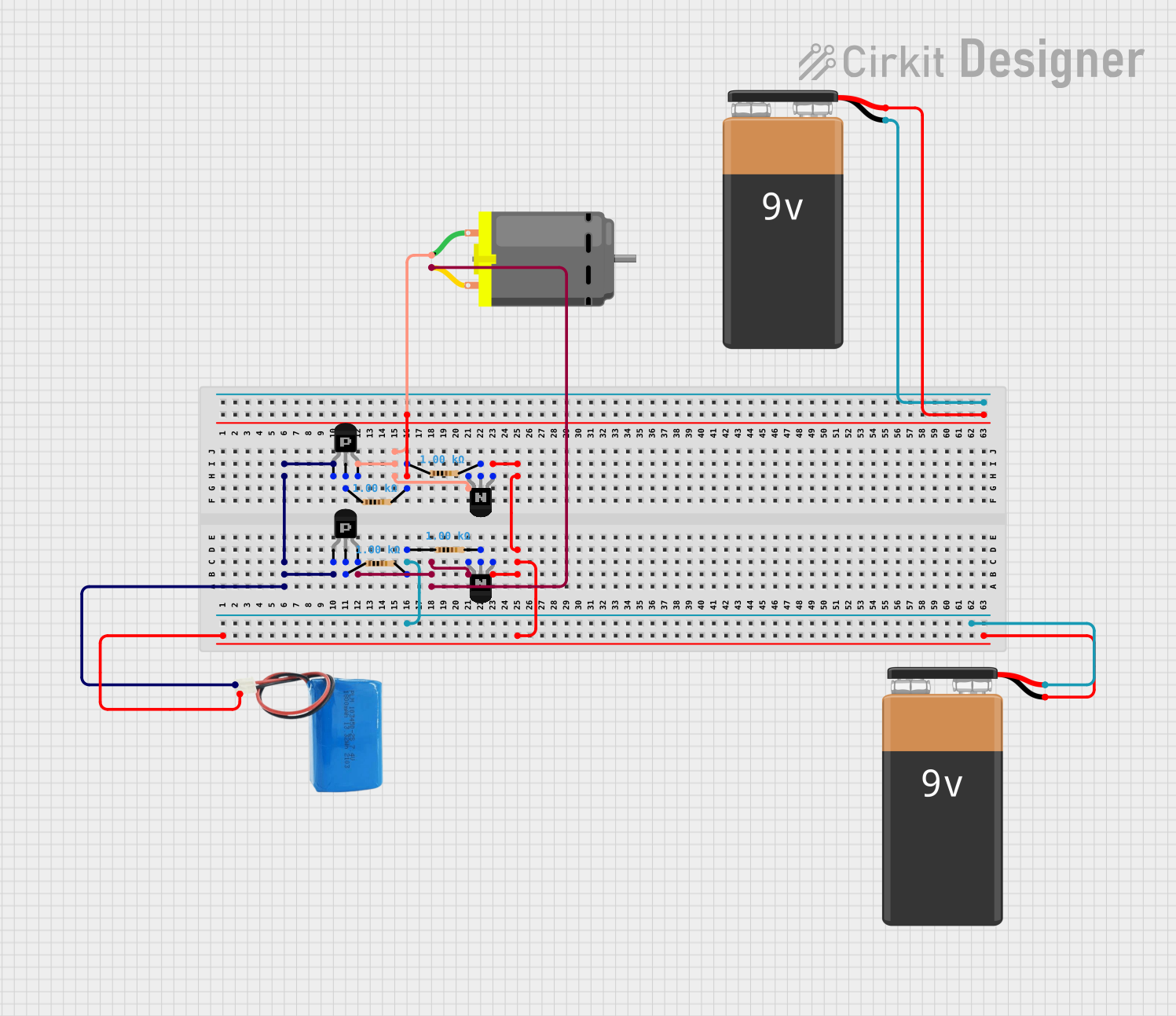

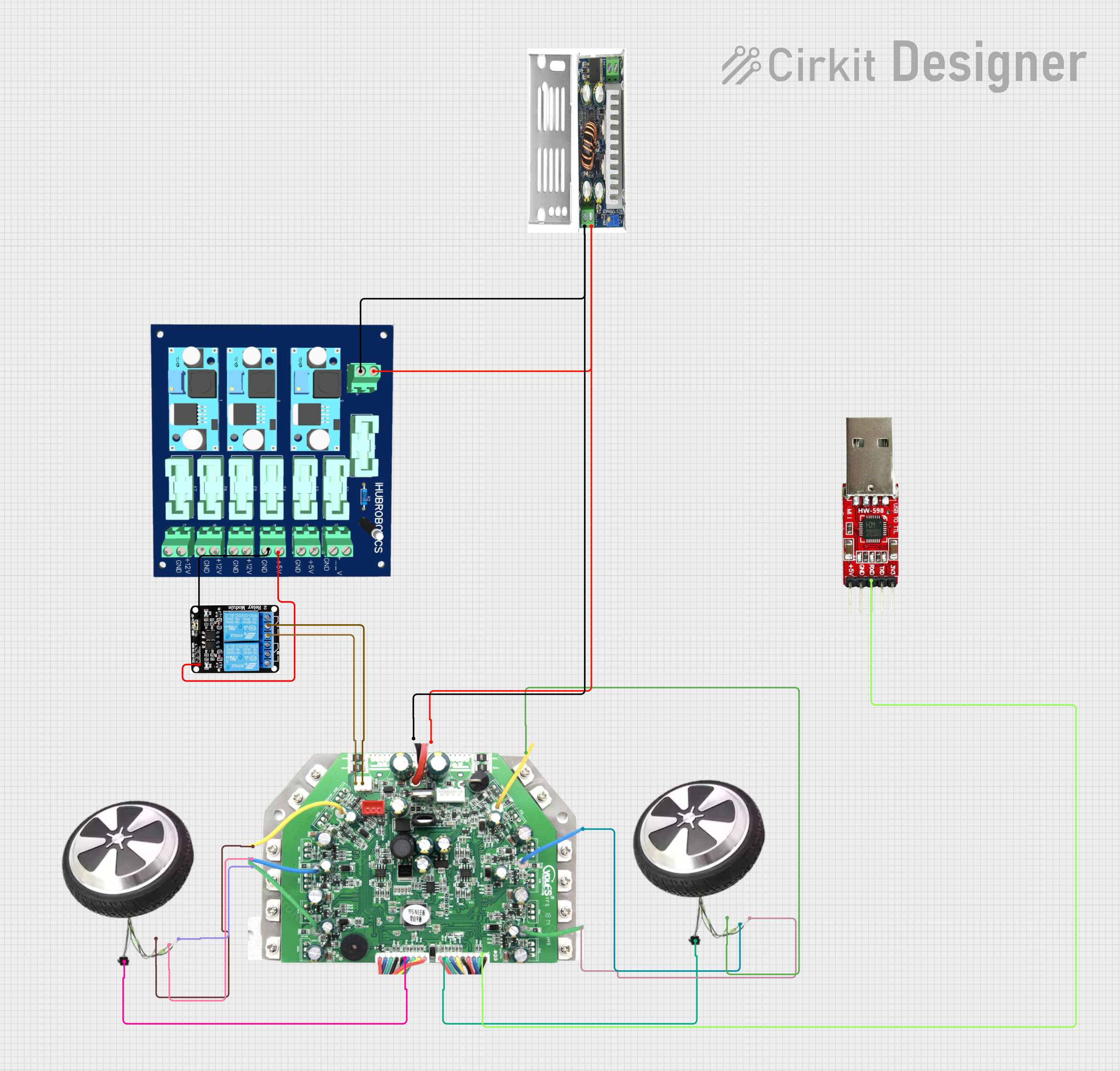

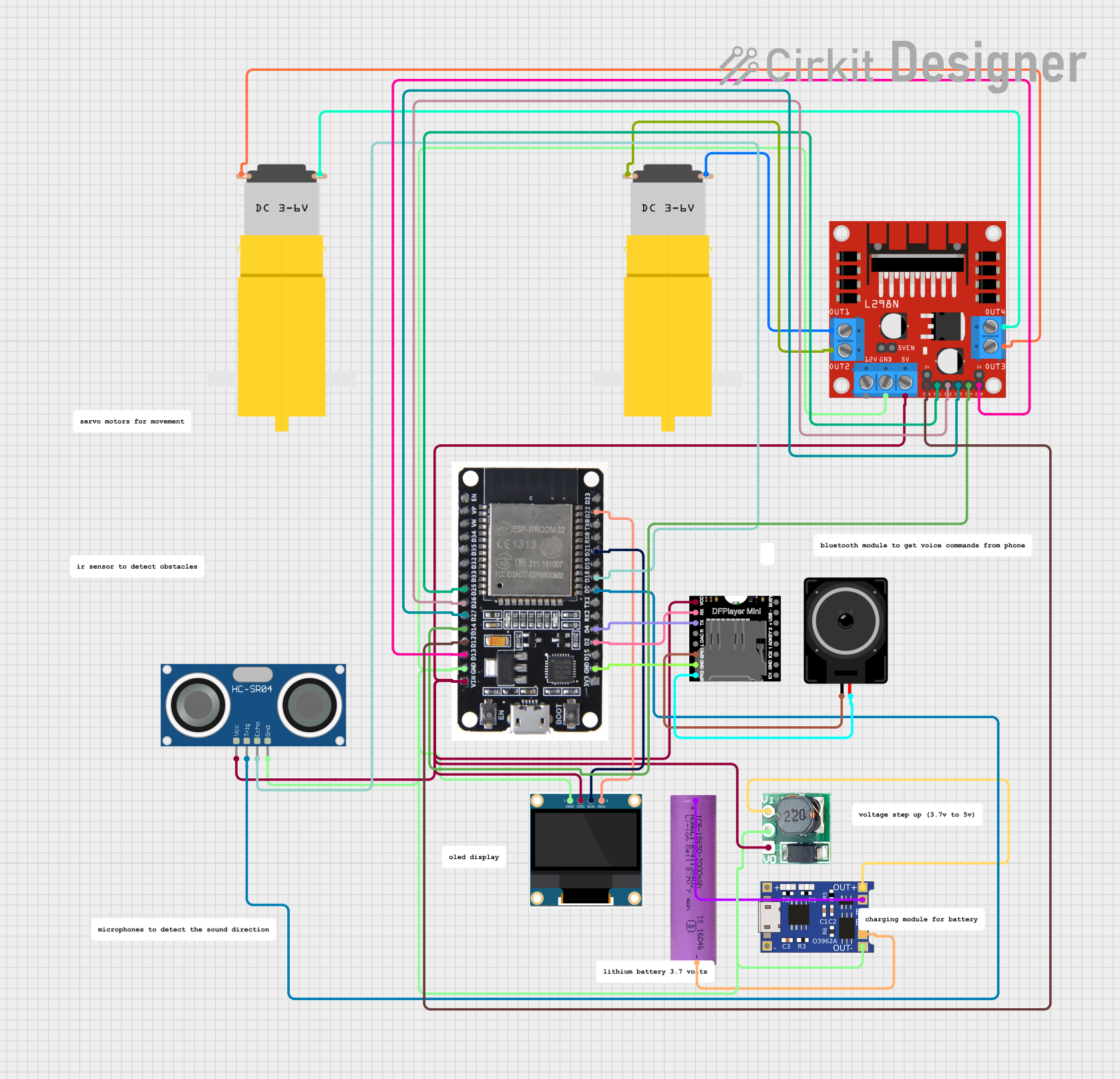

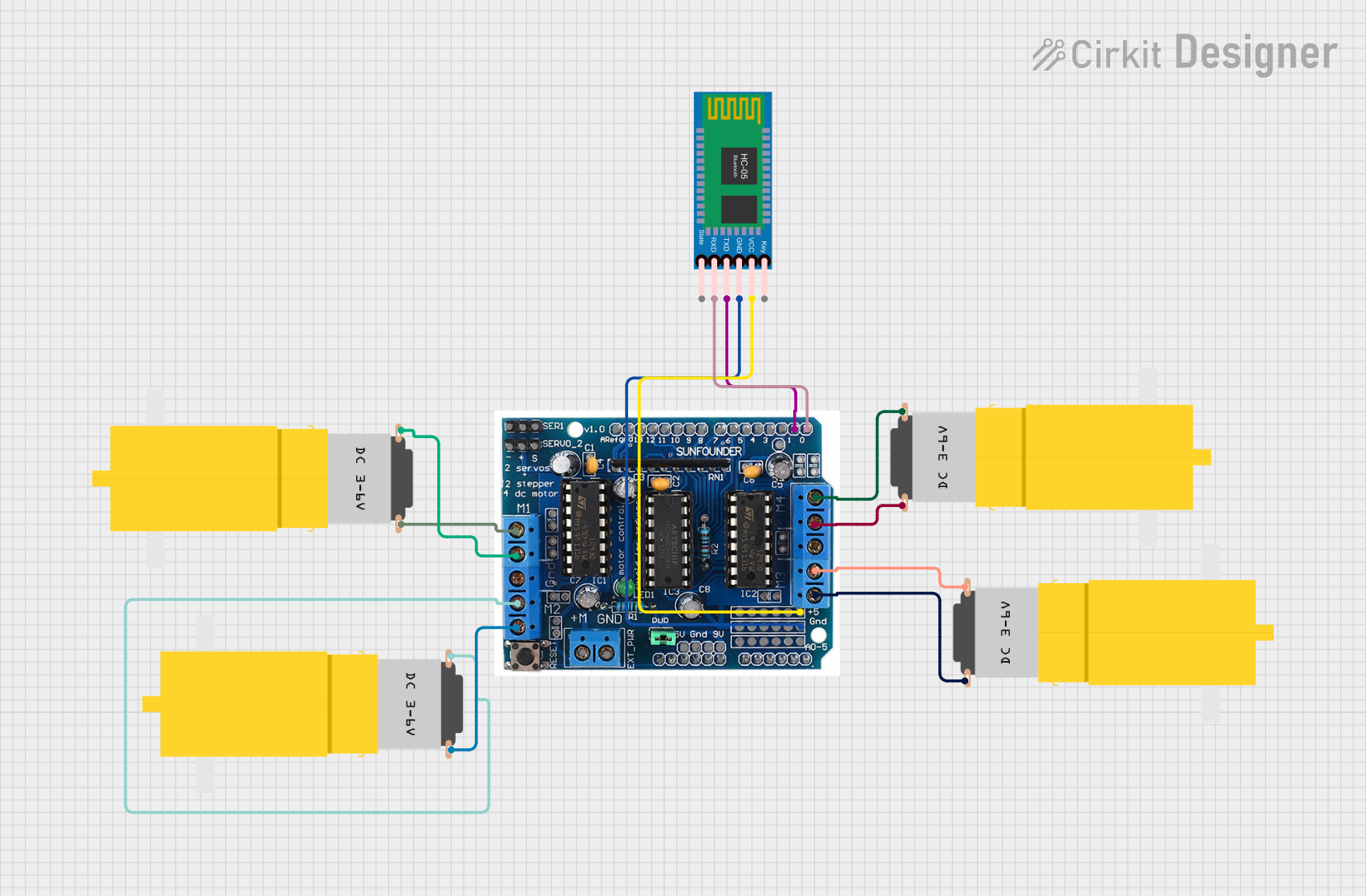

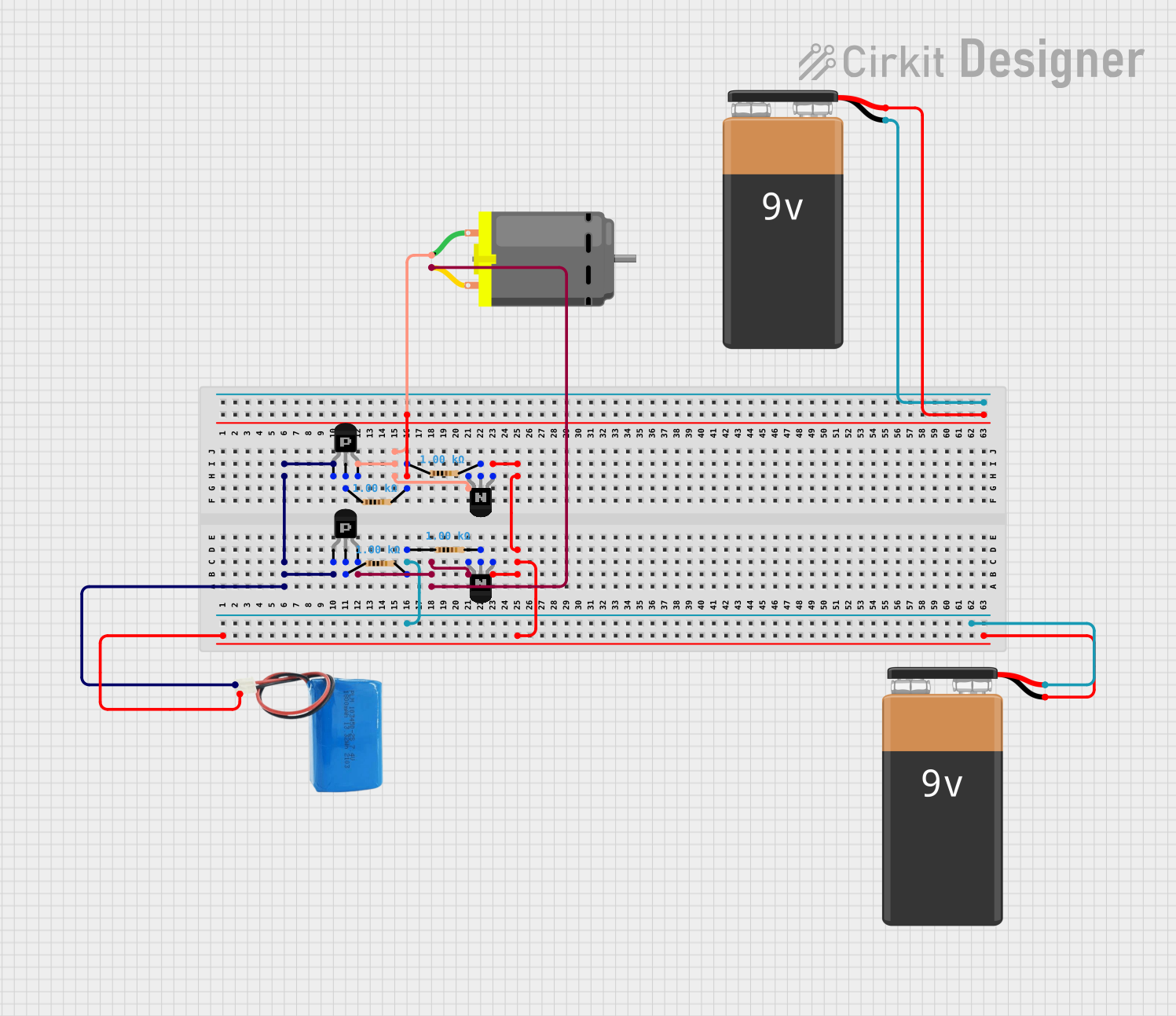

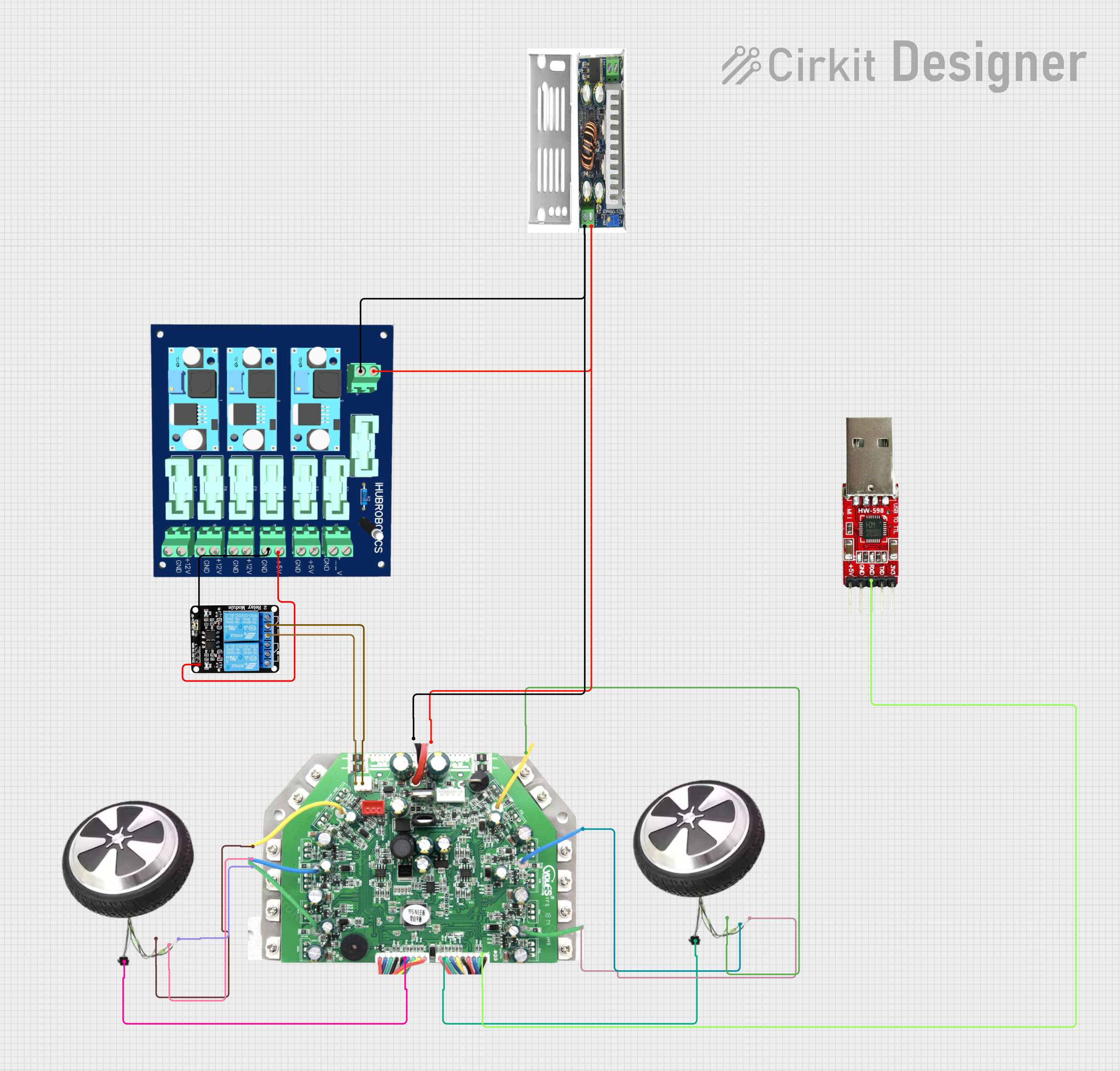

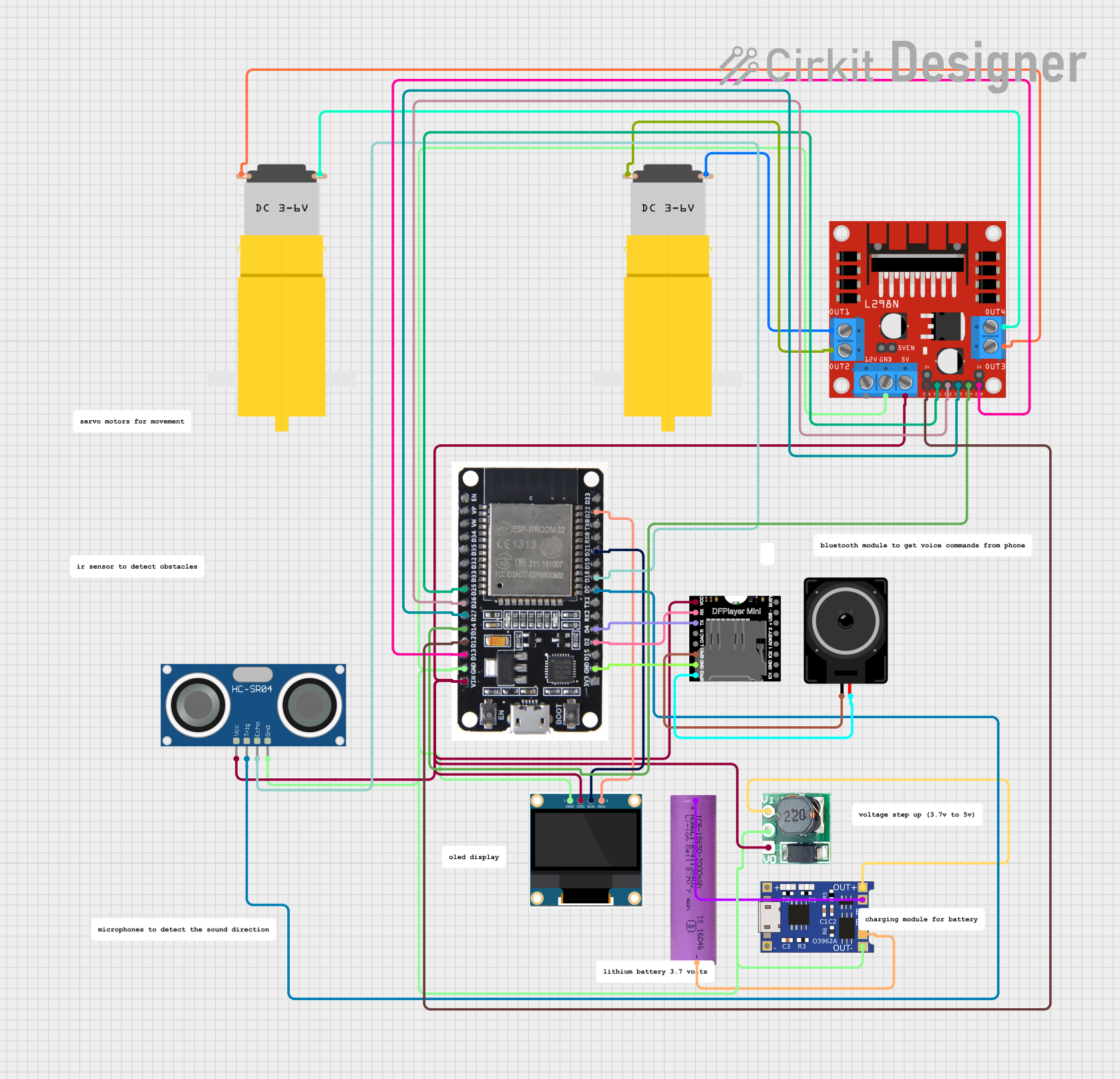

Explore Projects Built with PmodHB5_Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with PmodHB5_Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Driving motors for robotic arms, wheels, or tracks.

- Automation: Controlling conveyor belts, pumps, or fans.

- Educational Projects: Teaching motor control principles in STEM education.

- Hobby Projects: DIY projects requiring motor control, such as model vehicles.

Technical Specifications

Key Technical Details

- Operating Voltage: 4.5V to 16V

- Output Current: Up to 5A

- Control Signal: Digital PWM

- Direction Control: Forward and Reverse

- Protection Features: Overcurrent and thermal protection

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (4.5V to 16V) |

| 2 | GND | Ground connection |

| 3 | PWM | PWM input for speed control |

| 4 | DIR | Direction control input (High/Low) |

| 5 | SLEEP | Sleep mode enable (Active Low) |

| 6 | FAULT | Fault indication output (Active Low) |

Usage Instructions

How to Use the PmodHB5 in a Circuit

- Power Connections: Connect the VCC pin to a suitable power supply (4.5V to 16V) and the GND pin to the ground.

- Motor Connections: Attach the motor leads to the output terminals of the PmodHB5.

- Control Signal: Generate a PWM signal from your microcontroller and connect it to the PWM pin for speed control.

- Direction Control: Set the DIR pin high or low to control the motor's direction.

- Sleep Mode: Optionally, connect the SLEEP pin to a digital output on your microcontroller to enable or disable the driver.

- Fault Detection: Monitor the FAULT pin to detect any fault conditions such as overcurrent or overheating.

Important Considerations and Best Practices

- Ensure the power supply can handle the motor's current requirements.

- Use a decoupling capacitor close to the PmodHB5's power input to minimize voltage spikes.

- Avoid running the motor at full current for extended periods to prevent overheating.

- Implement an adequate cooling system if operating near the maximum current rating.

- Always check the motor's specifications to ensure compatibility with the driver's capabilities.

Example Code for Arduino UNO

// Define the pins connected to the PmodHB5

const int pwmPin = 3; // PWM input for speed control

const int dirPin = 4; // Direction control input

void setup() {

// Set the motor control pins as outputs

pinMode(pwmPin, OUTPUT);

pinMode(dirPin, OUTPUT);

}

void loop() {

// Set motor direction to forward

digitalWrite(dirPin, HIGH);

// Ramp up the motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmPin, speed);

delay(10);

}

// Ramp down the motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmPin, speed);

delay(10);

}

// Change motor direction to reverse

digitalWrite(dirPin, LOW);

// Repeat the ramp up and ramp down process

// ...

}

Troubleshooting and FAQs

Common Issues

- Motor not running: Check power supply connections and ensure the PWM signal is being generated.

- Overheating: Ensure the motor's current draw is within the module's limits and improve cooling if necessary.

- Fault indicator active: Check for overcurrent conditions or wiring errors.

Solutions and Tips for Troubleshooting

- Verify all connections are secure and correct.

- Use a multimeter to check the power supply voltage and motor resistance.

- Ensure the PWM frequency is within the acceptable range for the PmodHB5.

- If the FAULT pin is active, disconnect the power and inspect the motor and driver for any signs of damage.

FAQs

Q: Can I control two motors with one PmodHB5? A: No, the PmodHB5 is designed to control one motor at a time.

Q: What is the maximum PWM frequency the PmodHB5 can handle? A: Please refer to the datasheet for the maximum PWM frequency specifications.

Q: How do I know if the PmodHB5 is in fault mode? A: The FAULT pin will be pulled low when a fault is detected. Monitoring this pin with a microcontroller can alert you to any issues.

Q: Can I use the PmodHB5 with a 3.3V logic level microcontroller? A: Yes, but ensure that the logic level is compatible with the PmodHB5's input thresholds. Use a level shifter if necessary.