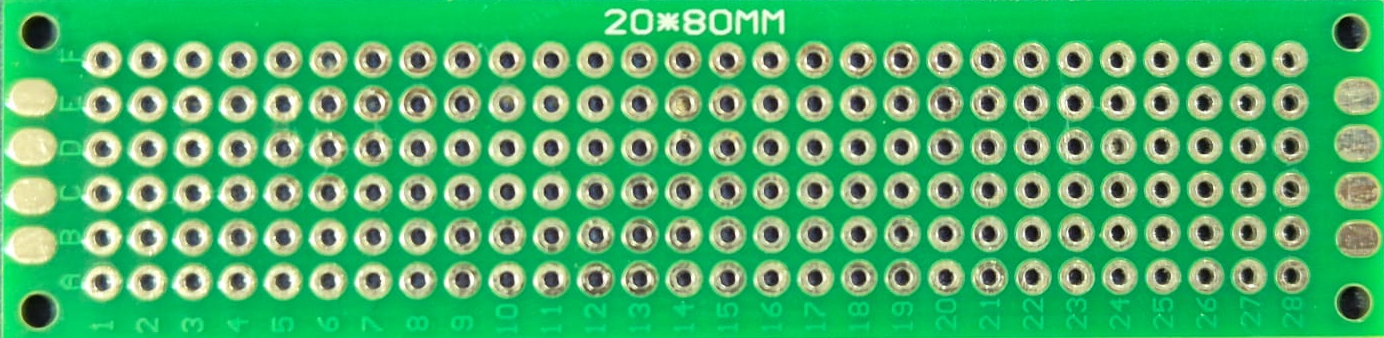

How to Use 20x80mm perf board: Examples, Pinouts, and Specs

Design with 20x80mm perf board in Cirkit Designer

Design with 20x80mm perf board in Cirkit DesignerIntroduction

The 20x80mm perf board is a compact, perforated board designed for prototyping electronic circuits. It features a grid of evenly spaced holes that allow users to mount components and create custom circuit layouts. This versatile tool is ideal for hobbyists, students, and professionals who need a reliable platform for testing and building electronic designs.

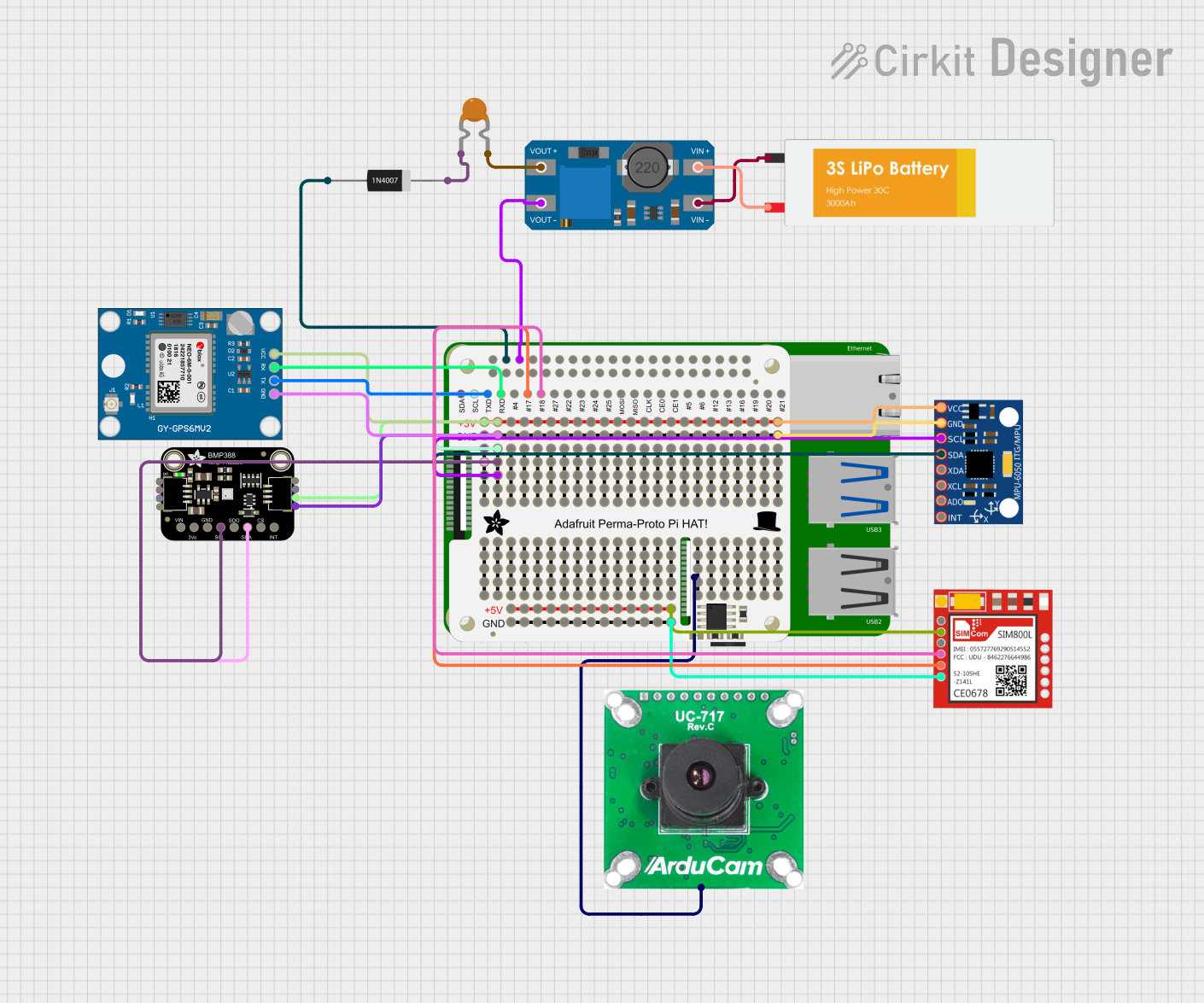

Explore Projects Built with 20x80mm perf board

Open Project in Cirkit Designer

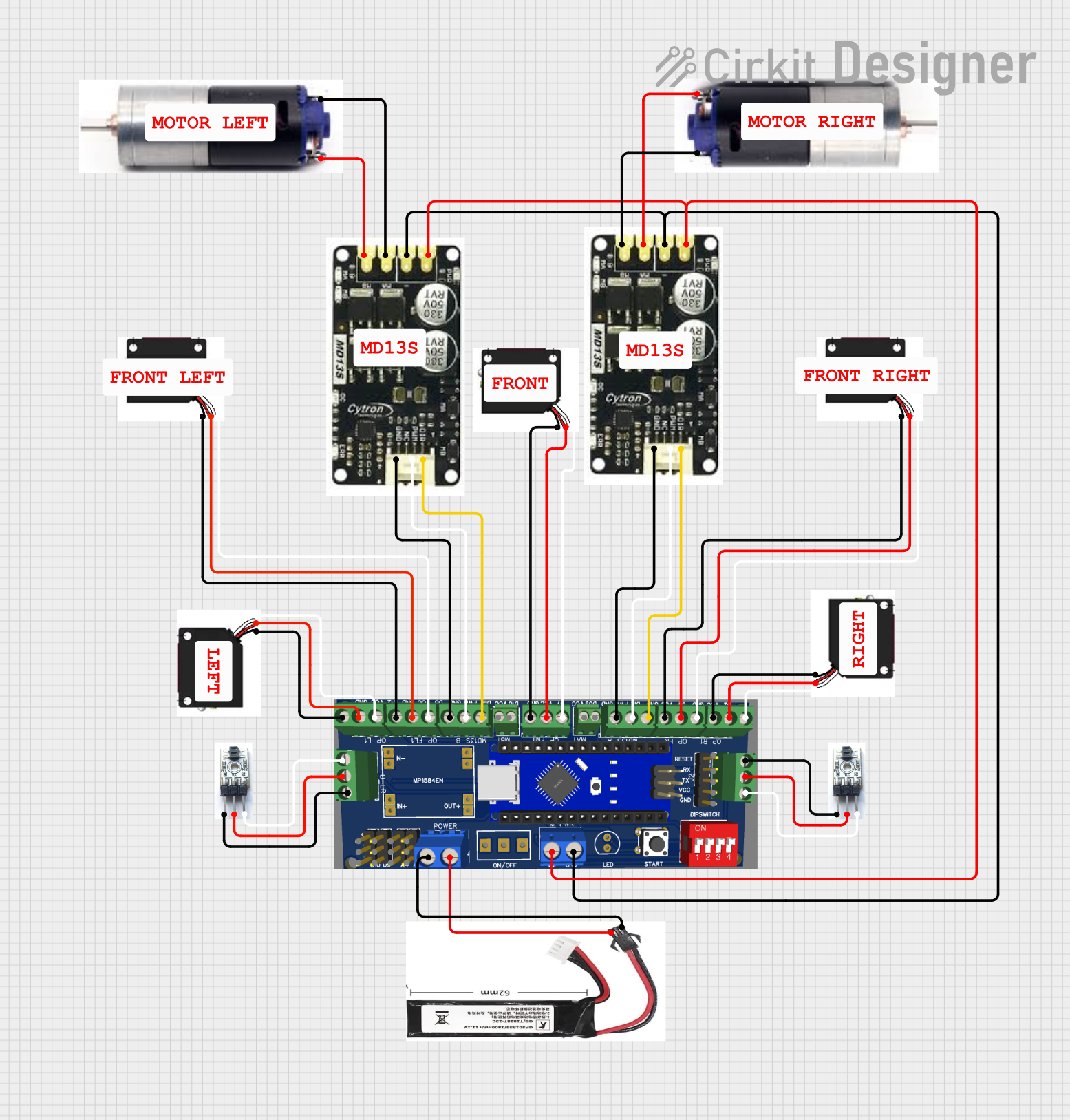

Open Project in Cirkit Designer

Open Project in Cirkit Designer

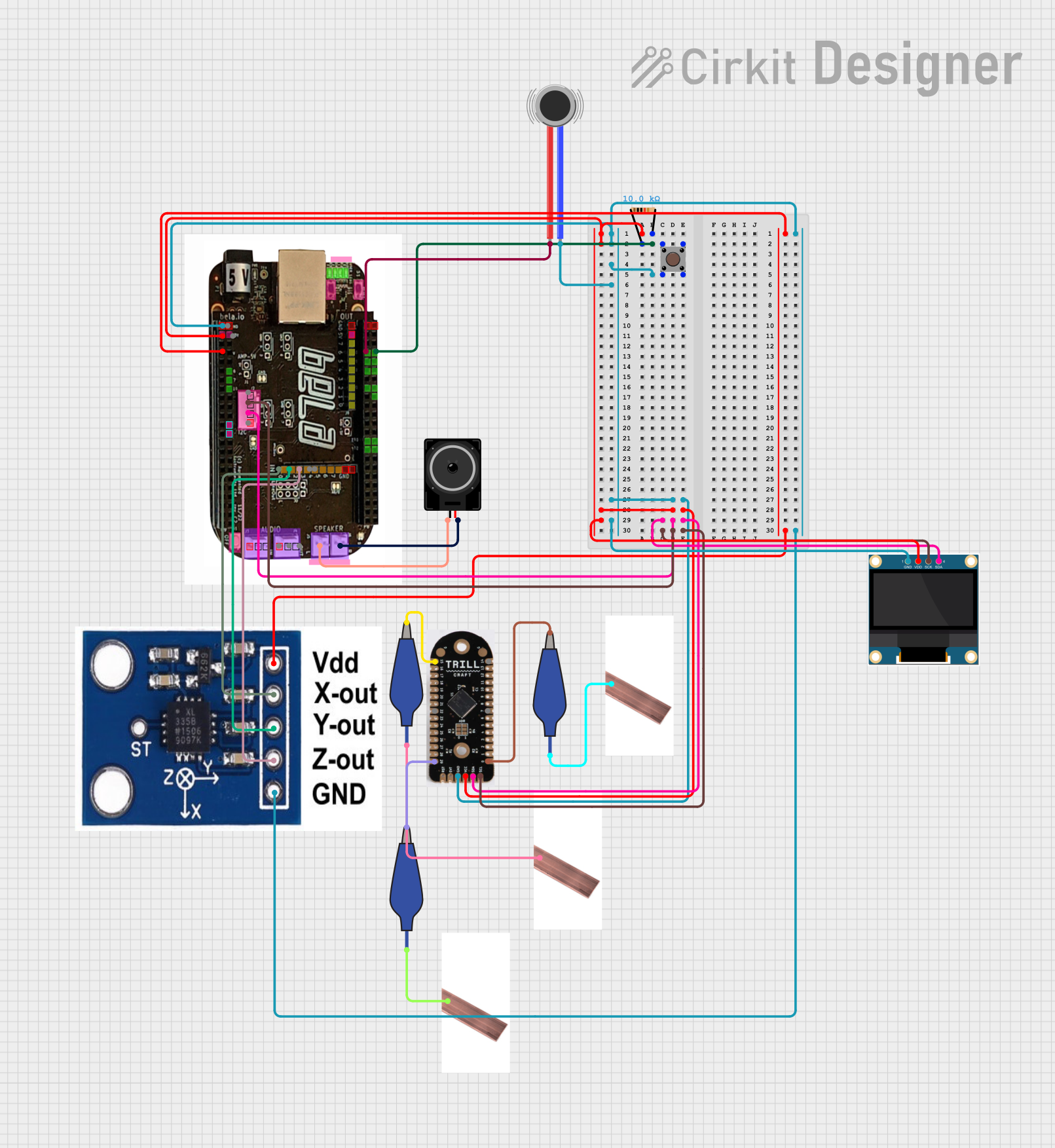

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 20x80mm perf board

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Prototyping and testing small electronic circuits

- Building custom circuit boards for DIY projects

- Educational purposes for learning circuit design

- Repairing or modifying existing circuits

- Creating compact, permanent circuit solutions

Technical Specifications

The 20x80mm perf board is designed to provide a durable and flexible platform for circuit prototyping. Below are its key specifications:

| Specification | Details |

|---|---|

| Dimensions | 20mm x 80mm |

| Material | FR4 (fiberglass-reinforced epoxy) |

| Hole Grid | 2.54mm (0.1 inch) pitch |

| Hole Diameter | ~1.0mm |

| Thickness | ~1.6mm |

| Copper Layer | Single-sided or double-sided (varies) |

| Weight | ~5g |

Pin Configuration and Descriptions

The perf board does not have predefined pins but features a grid of holes for mounting components. Below is a description of its layout:

| Feature | Description |

|---|---|

| Holes | Arranged in a 2.54mm pitch grid for mounting through-hole components. |

| Copper Pads | May be present around holes (depending on the type) to facilitate soldering. |

| Edges | Smooth edges for safe handling and easy mounting in enclosures. |

Usage Instructions

How to Use the 20x80mm Perf Board in a Circuit

- Plan Your Circuit Layout: Sketch the circuit design on paper or use software to map out the placement of components.

- Insert Components: Place through-hole components (e.g., resistors, capacitors, ICs) into the holes of the perf board.

- Solder Connections: Use a soldering iron to secure the components to the board. Ensure proper solder joints for reliable connections.

- Wire Connections: Use jumper wires or soldered connections to link components as per your circuit design.

- Test the Circuit: Verify the functionality of your circuit using a multimeter or by powering it up.

Important Considerations and Best Practices

- Component Placement: Leave enough space between components to avoid short circuits and make soldering easier.

- Heat Management: Avoid overheating the board while soldering to prevent damage to the copper pads or the board itself.

- Insulation: Use heat-shrink tubing or electrical tape to insulate exposed wires and prevent accidental shorts.

- Cutting the Board: If needed, the board can be cut to a smaller size using a hacksaw or rotary tool. Sand the edges for a smooth finish.

- Arduino Compatibility: The 20x80mm perf board can be used to create custom shields or circuits for Arduino UNO and other microcontrollers.

Example: Connecting an LED to an Arduino UNO

Below is an example of how to use the perf board to connect an LED to an Arduino UNO:

- Place the LED and a 220-ohm resistor on the perf board.

- Solder the anode of the LED to one end of the resistor.

- Connect the other end of the resistor to a jumper wire leading to Arduino pin 13.

- Solder the cathode of the LED to a wire leading to the Arduino GND pin.

// Arduino code to blink an LED connected to pin 13

void setup() {

pinMode(13, OUTPUT); // Set pin 13 as an output

}

void loop() {

digitalWrite(13, HIGH); // Turn the LED on

delay(1000); // Wait for 1 second

digitalWrite(13, LOW); // Turn the LED off

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Loose Connections: Components may not be securely soldered, leading to intermittent connections.

- Solution: Re-solder the joints, ensuring a clean and solid connection.

- Short Circuits: Solder bridges between adjacent pads can cause short circuits.

- Solution: Use a soldering iron and desoldering wick to remove excess solder.

- Overheating the Board: Excessive heat during soldering can damage the board or lift copper pads.

- Solution: Use a temperature-controlled soldering iron and work quickly.

- Incorrect Layout: Misplaced components or incorrect wiring can lead to non-functional circuits.

- Solution: Double-check the circuit design and verify connections with a multimeter.

FAQs

Q: Can I reuse a perf board after soldering?

A: Yes, but it can be challenging to remove soldered components without damaging the board. Use a desoldering pump or wick for best results.

Q: Is the perf board suitable for high-current applications?

A: Perf boards are generally not designed for high-current circuits. Use thicker wires and ensure proper heat dissipation if needed.

Q: Can I use surface-mount components on a perf board?

A: While perf boards are designed for through-hole components, surface-mount components can be used with careful soldering and additional wiring.

Q: How do I cut the perf board to a custom size?

A: Use a hacksaw or rotary tool to cut the board. Sand the edges to remove sharp edges and debris.