How to Use MAIN CONTACTOR: Examples, Pinouts, and Specs

Design with MAIN CONTACTOR in Cirkit Designer

Design with MAIN CONTACTOR in Cirkit DesignerIntroduction

A main contactor, manufactured by NIXON, is an electromechanical switch used for switching an electrical power circuit. It is similar to a relay but is designed to handle higher current loads and is thus commonly used in industrial and commercial electrical systems. Main contactors are essential components in controlling the flow of electricity in heavy machinery, motor controllers, lighting systems, and heating, ventilation, and air conditioning (HVAC) applications.

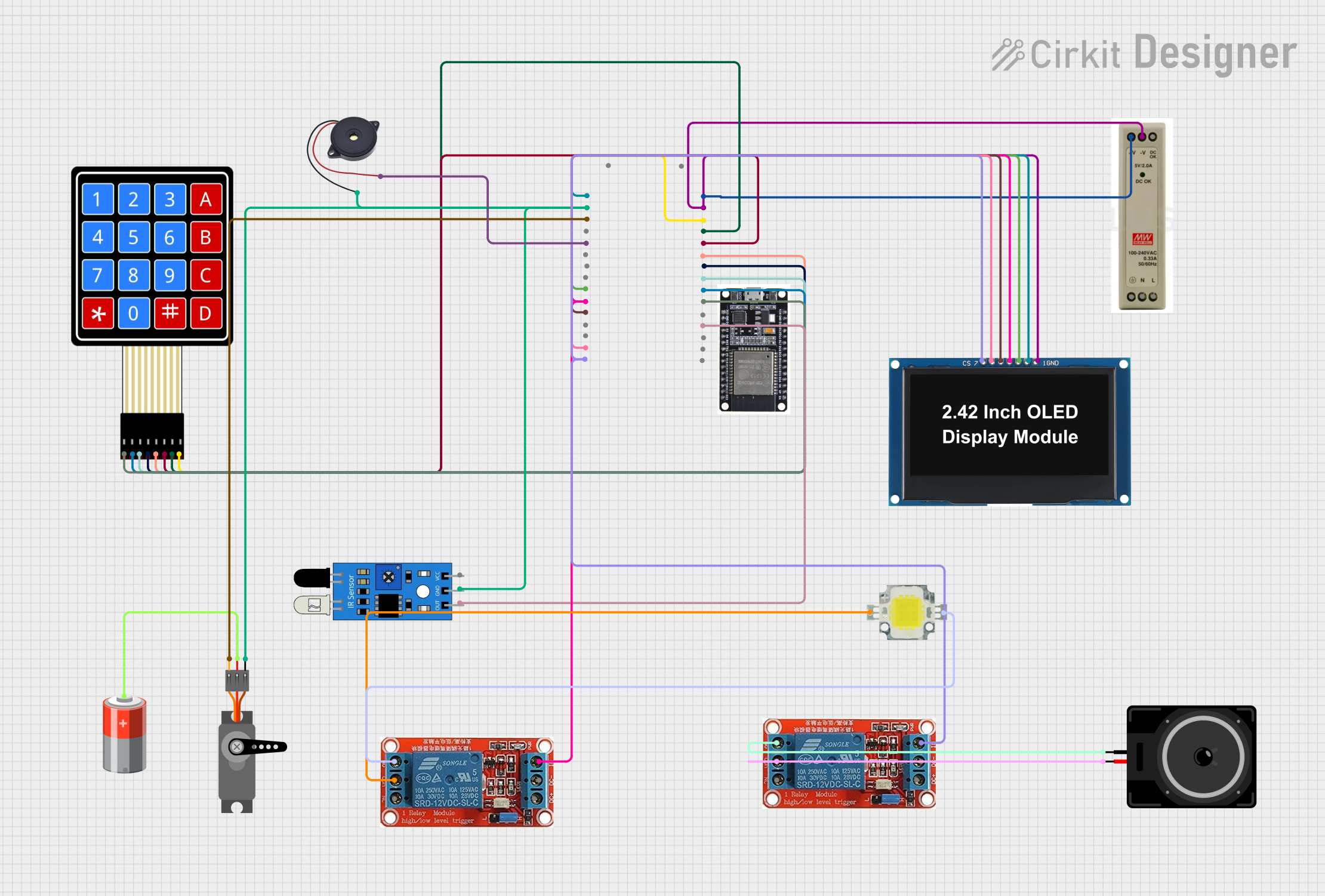

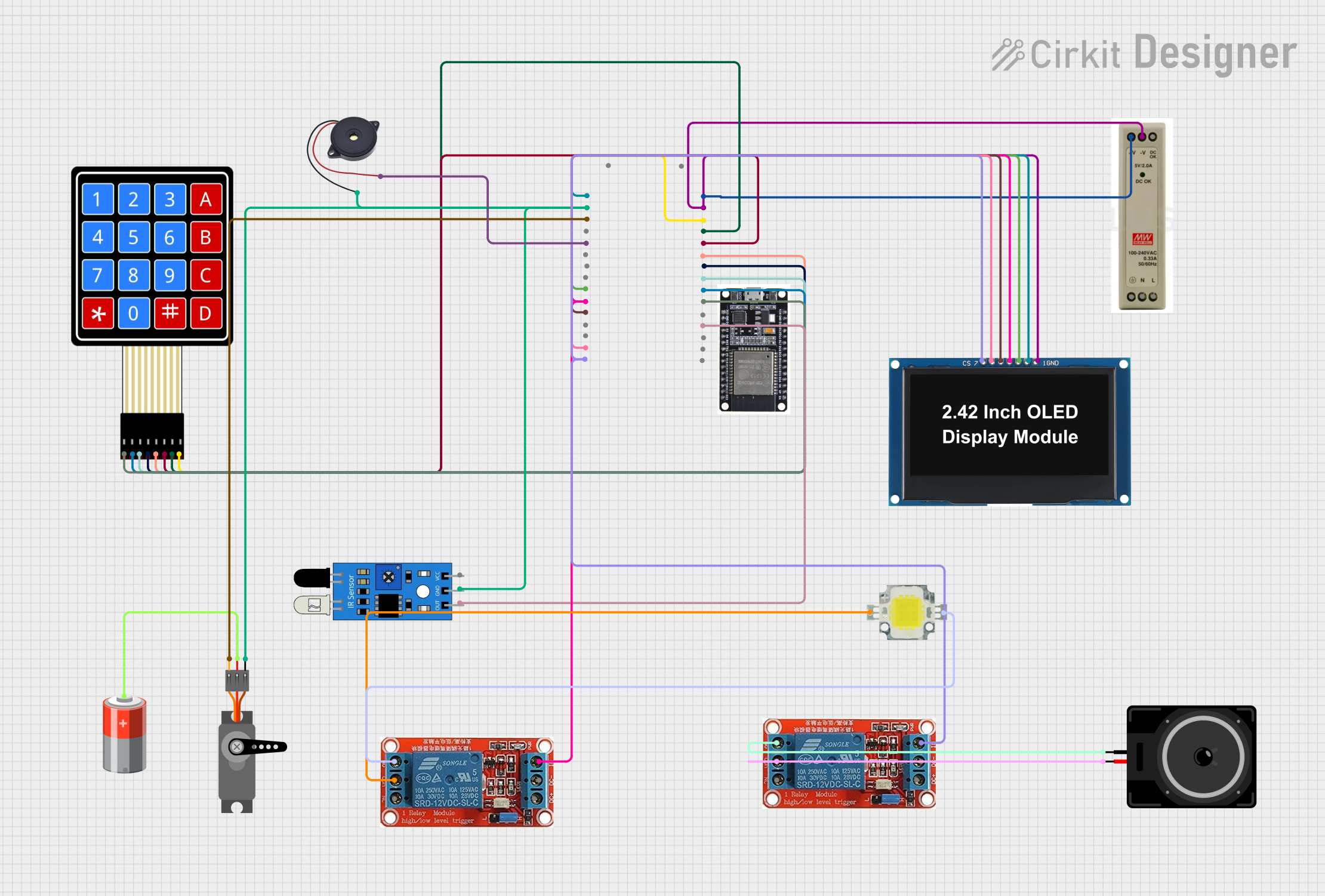

Explore Projects Built with MAIN CONTACTOR

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MAIN CONTACTOR

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Manufacturer: NIXON

- Component Type: Main Contactor

- Control Voltage: Typically ranges from 24V to 480V AC/DC

- Rated Operational Current: Up to several hundred amperes (exact value to be specified)

- Rated Operational Voltage: Up to 600V AC

- Frequency: 50/60 Hz

- Number of Poles: 3 or 4 poles (common configurations)

- Contact Material: Silver alloy or similar high-conductivity, high-wear material

- Mechanical Life: Several million operations

- Electrical Life: Depends on load and operating conditions

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| A1 | Coil input (+) | Control voltage positive terminal |

| A2 | Coil input (-) | Control voltage negative terminal |

| 1, 3, 5 | Power input terminals (L1, L2, L3) | Connect to power source |

| 2, 4, 6 | Power output terminals (T1, T2, T3) | Connect to load |

| NC | Normally closed auxiliary contact | Optional, for feedback or interlocking |

| NO | Normally open auxiliary contact | Optional, for feedback or interlocking |

Note: The pin configuration may vary depending on the specific model and manufacturer. Always refer to the manufacturer's datasheet for exact details.

Usage Instructions

Integration into a Circuit

- Power Source Connection: Connect the power source lines to the input terminals (1, 3, 5) of the contactor.

- Load Connection: Connect the load to the output terminals (2, 4, 6) of the contactor.

- Control Signal: Apply the control voltage to the coil terminals (A1 and A2) to engage the contactor.

Best Practices

- Ensure that the contactor's ratings match or exceed the requirements of the application.

- Use appropriate cable sizes to handle the current without overheating.

- Install a surge suppressor or varistor across the coil terminals to protect against voltage spikes.

- Regularly inspect the contactor for signs of wear or damage, especially the contacts and coil.

- Provide adequate ventilation to prevent overheating during operation.

Troubleshooting and FAQs

Common Issues

- Contactor Does Not Engage: Check control voltage and coil connections. Ensure that the coil is not damaged.

- Excessive Noise or Chatter: Verify that the control voltage is stable and within the specified range.

- Contacts Not Closing Properly: Inspect for physical damage or debris. Consider replacing the contactor if contacts are worn out.

FAQs

Q: Can a main contactor be used for DC applications? A: Yes, but ensure that the contactor is rated for DC operation, as AC and DC ratings may differ.

Q: How do I know if the contactor coil is energized? A: Some contactors have an indicator or an auxiliary contact that can be used to signal when the coil is energized.

Q: What is the purpose of auxiliary contacts? A: Auxiliary contacts are used for signaling, interlocking circuits, or adding additional control logic.

Example Code for Arduino UNO

The following example demonstrates how to control a NIXON main contactor using an Arduino UNO. The Arduino can be used to switch the contactor on and off with a digital output pin connected to a relay module that is interfaced with the contactor's coil.

// Define the pin connected to the relay module

const int relayPin = 7;

void setup() {

// Set the relay pin as an output

pinMode(relayPin, OUTPUT);

}

void loop() {

// Turn on the contactor (relay module activation)

digitalWrite(relayPin, HIGH);

delay(5000); // Keep the contactor on for 5 seconds

// Turn off the contactor (relay module deactivation)

digitalWrite(relayPin, LOW);

delay(5000); // Keep the contactor off for 5 seconds

}

Note: The above code assumes the use of a relay module that is compatible with the Arduino's 5V logic level. The relay module should be capable of handling the control voltage required by the contactor's coil.

Important: Always ensure that the relay module used is rated for the contactor's coil voltage and current. Directly connecting the contactor to the Arduino without a relay module can damage the microcontroller.