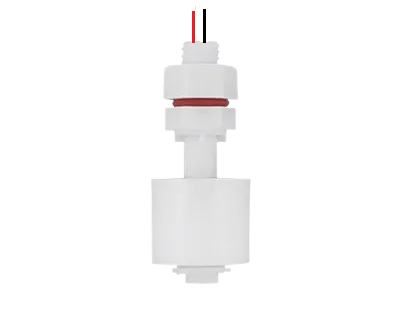

How to Use float sensor: Examples, Pinouts, and Specs

Design with float sensor in Cirkit Designer

Design with float sensor in Cirkit DesignerIntroduction

A float sensor, manufactured by R.M ENTERPRISE with part ID SENSOR, is a device designed to detect the level of liquid within a tank or container. It operates using a buoyant float that moves with the liquid level, triggering a switch or sending a signal when a predefined level is reached. This simple yet effective mechanism makes it a reliable choice for liquid level monitoring.

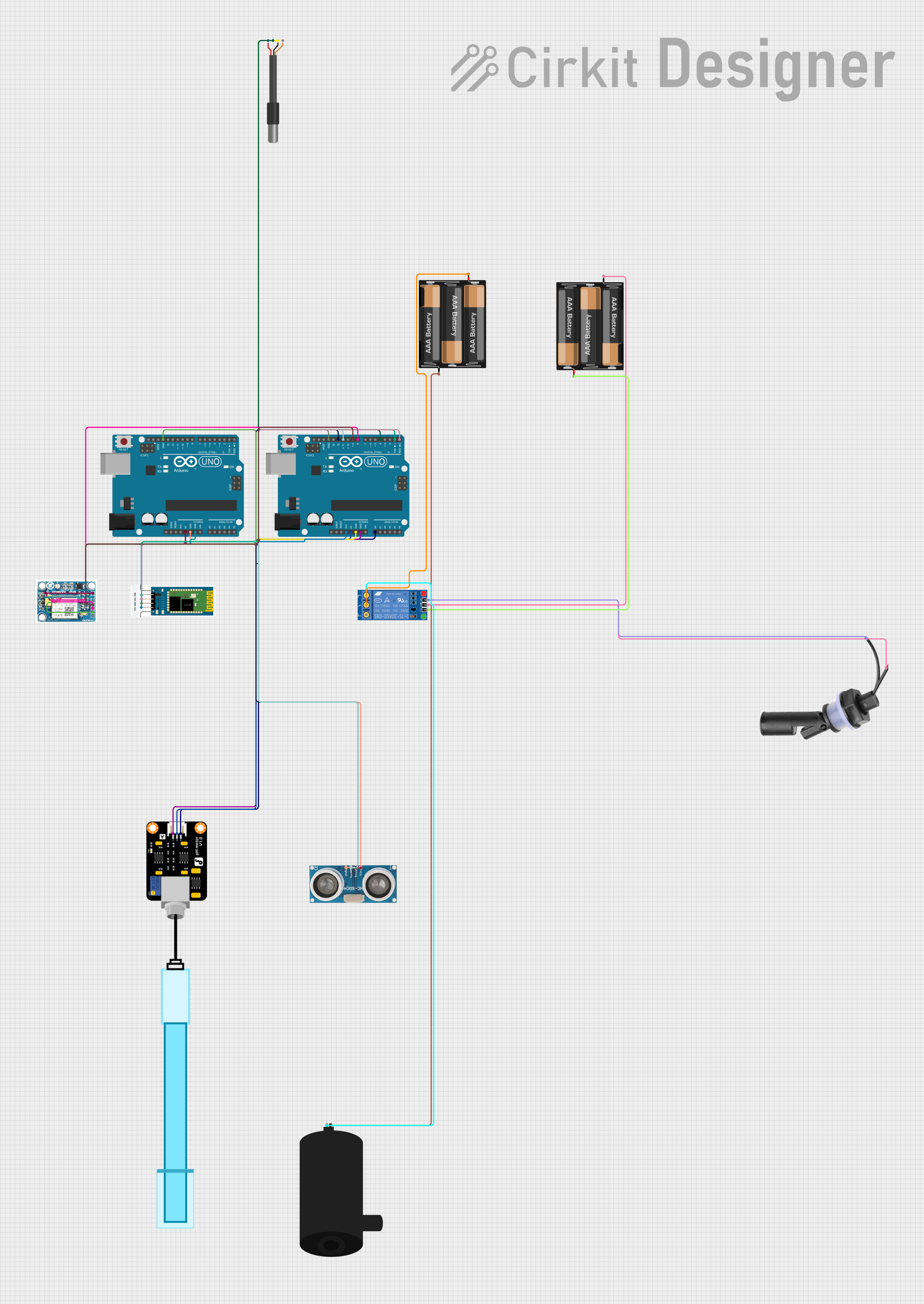

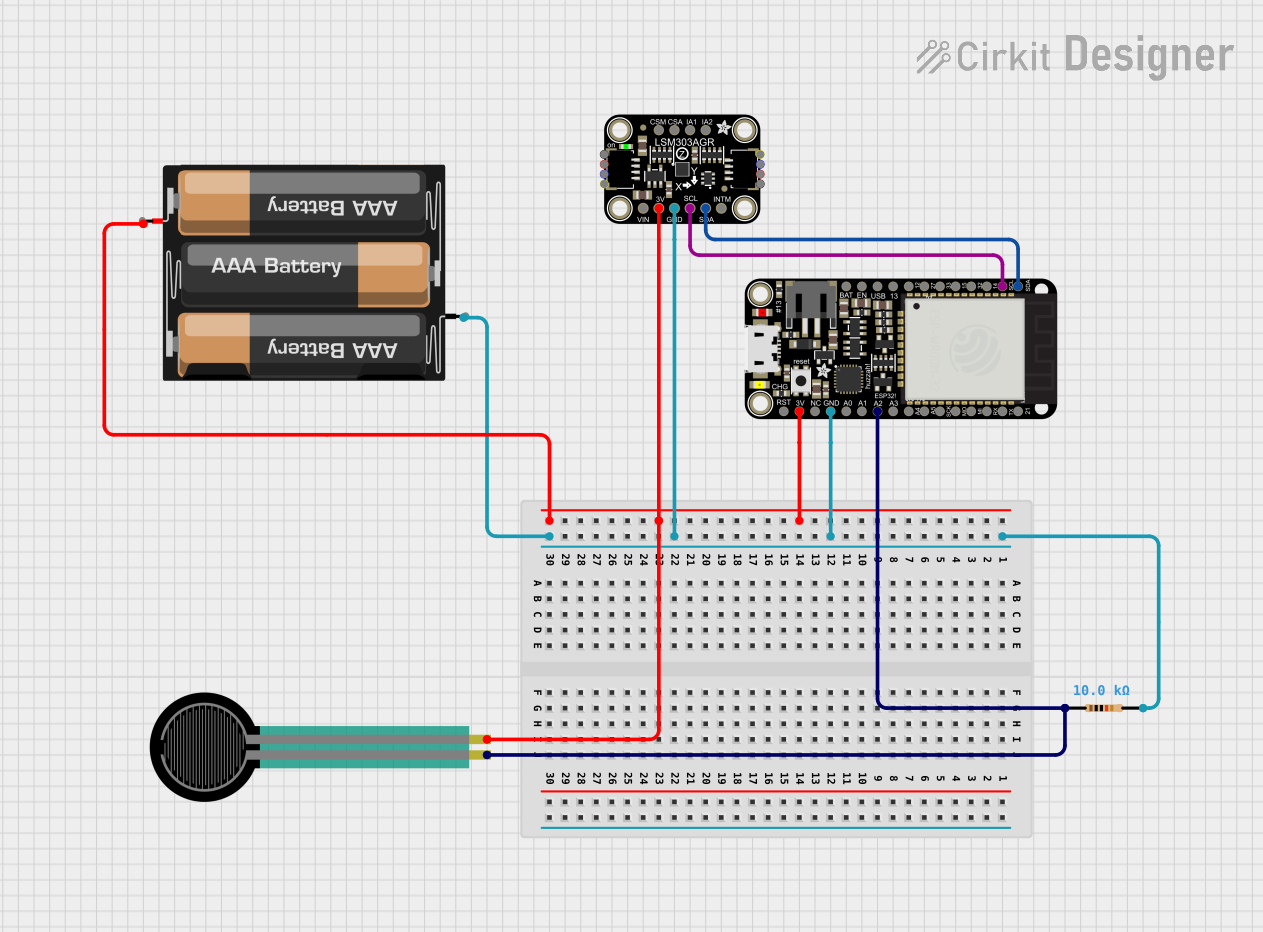

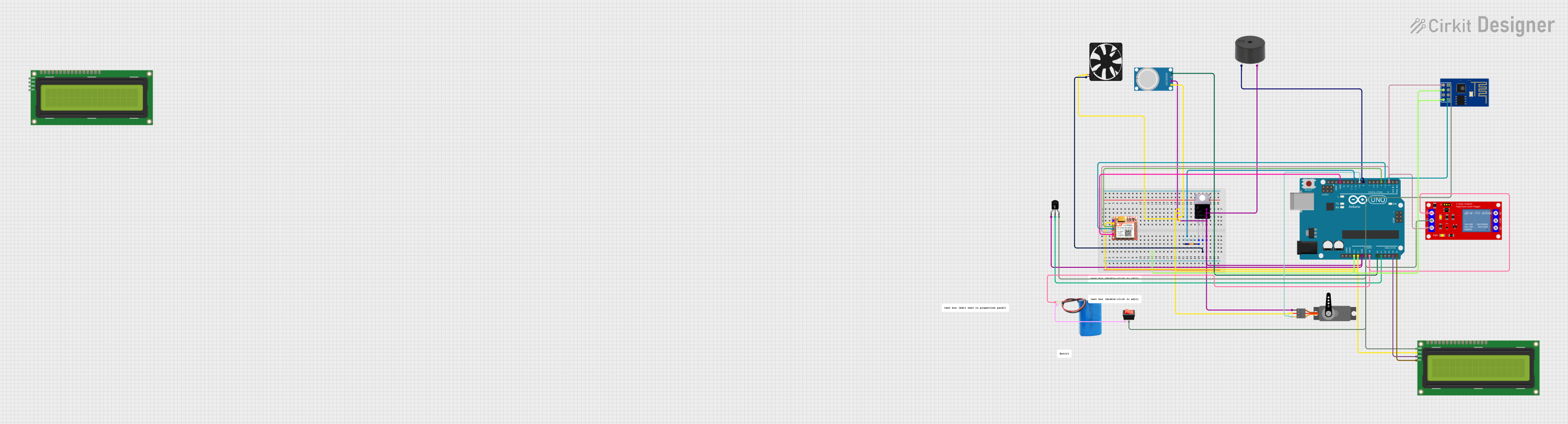

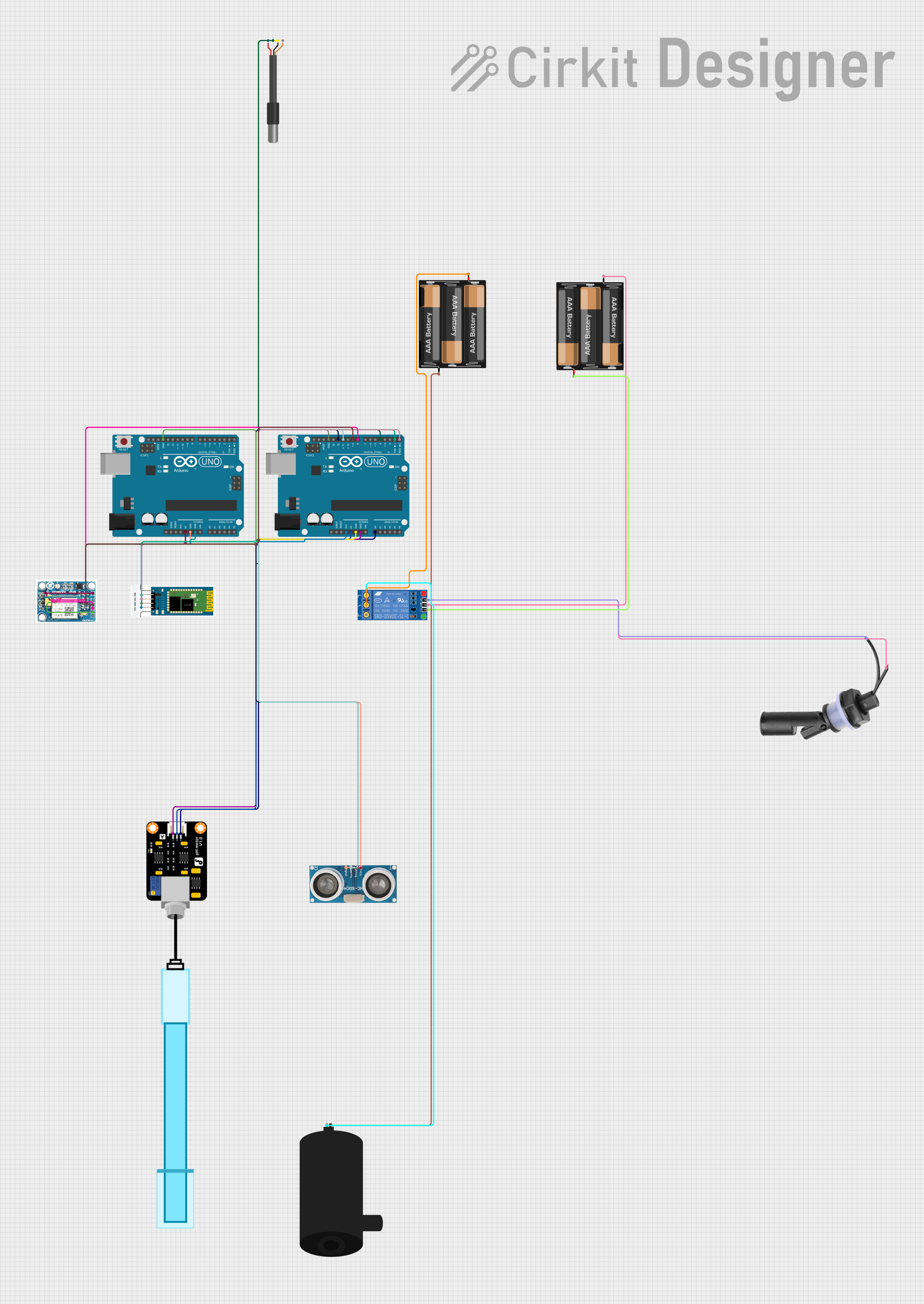

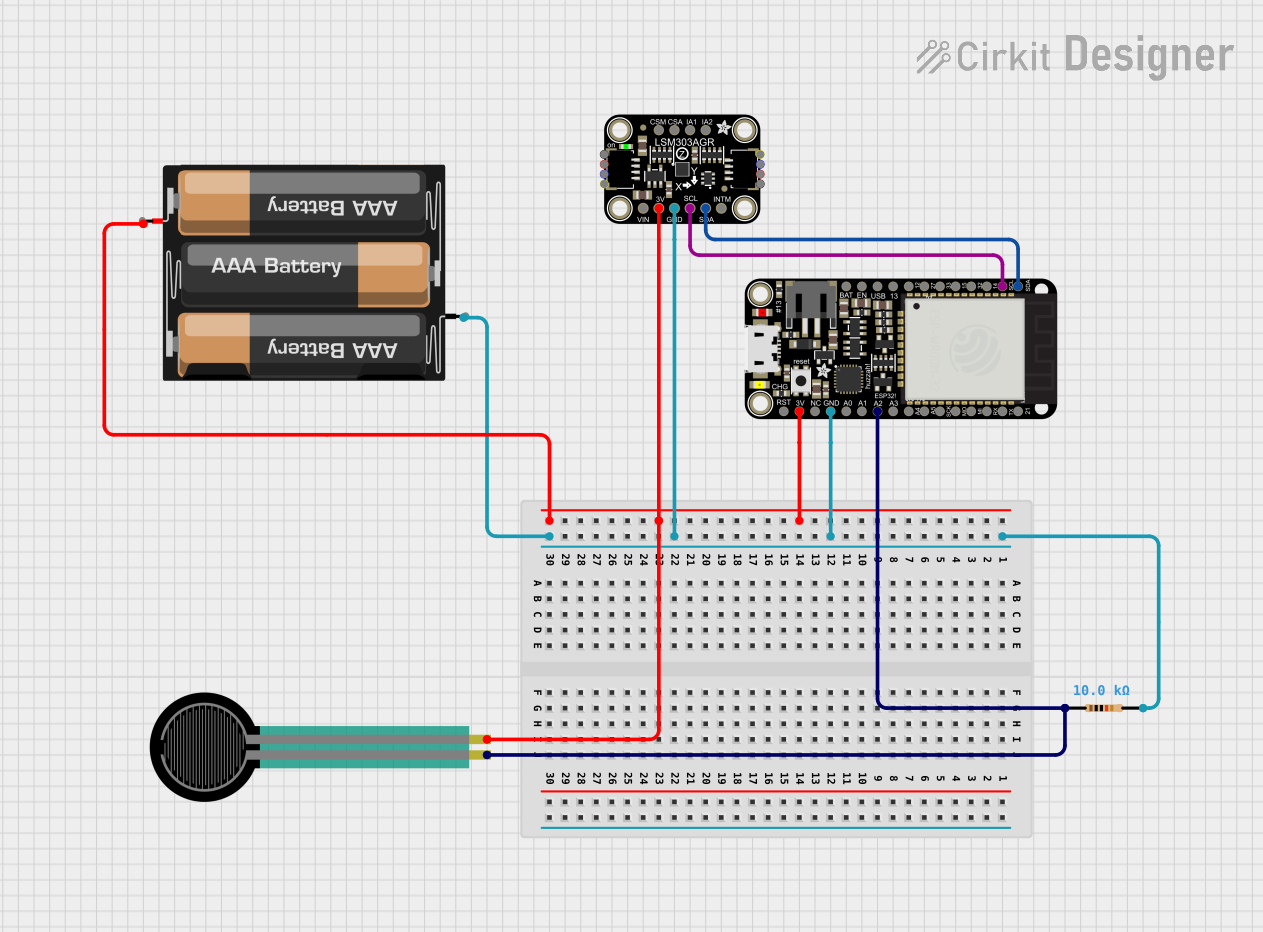

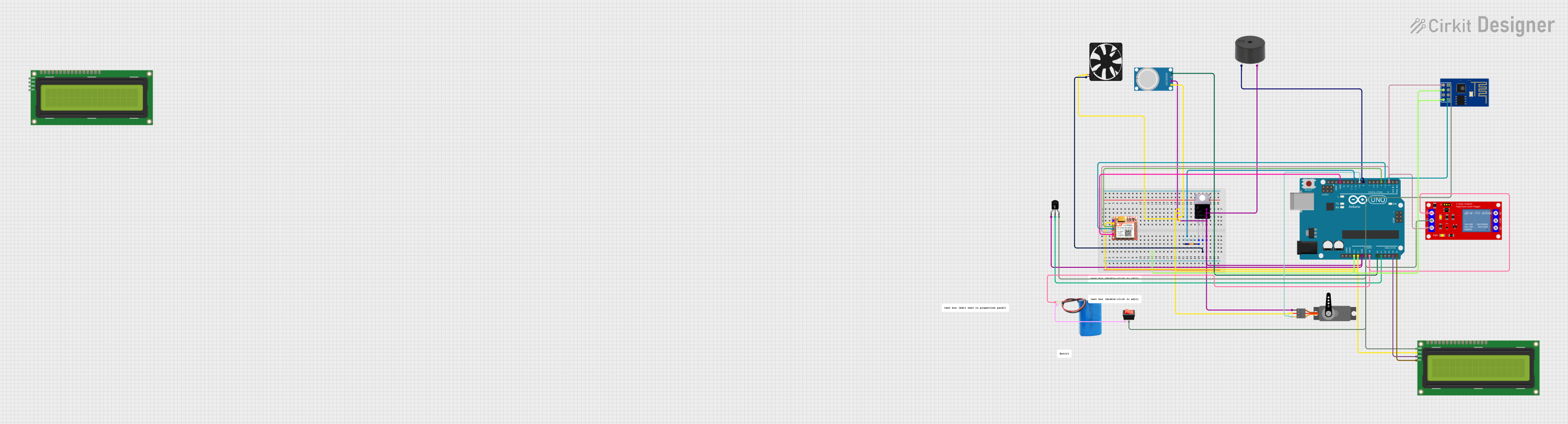

Explore Projects Built with float sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with float sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Water level monitoring in tanks and reservoirs

- Industrial liquid level control systems

- Home automation for water pumps

- Fuel level detection in vehicles

- Overflow and dry-run protection in pumps

Technical Specifications

The following table outlines the key technical details of the float sensor:

| Parameter | Specification |

|---|---|

| Manufacturer | R.M ENTERPRISE |

| Part ID | SENSOR |

| Operating Voltage | 5V to 24V DC |

| Maximum Current Rating | 500mA |

| Contact Type | Normally Open (NO) or Normally Closed (NC) |

| Material | Polypropylene (PP) |

| Operating Temperature | -10°C to 85°C |

| Cable Length | 1 meter |

| Float Diameter | 28mm |

| Liquid Compatibility | Water, oil, and non-corrosive liquids |

Pin Configuration and Descriptions

The float sensor typically has two wires for connection. The table below describes the pinout:

| Wire Color | Description |

|---|---|

| Red | Positive terminal (connect to VCC) |

| Black | Negative terminal (connect to GND) |

Usage Instructions

How to Use the Float Sensor in a Circuit

Wiring the Sensor:

- Connect the red wire of the float sensor to the positive voltage supply (VCC).

- Connect the black wire to the ground (GND) of the circuit.

- If using the sensor with a microcontroller, connect the sensor output to a digital input pin.

Circuit Example:

- The float sensor can be used to control a water pump. When the liquid level drops below a certain point, the sensor can trigger the pump to turn on.

Arduino UNO Example Code: Below is an example of how to use the float sensor with an Arduino UNO to monitor water levels:

// Float Sensor Example Code // Connect the float sensor output to Arduino digital pin 2 const int floatSensorPin = 2; // Pin connected to the float sensor const int ledPin = 13; // Built-in LED for status indication void setup() { pinMode(floatSensorPin, INPUT); // Set the float sensor pin as input pinMode(ledPin, OUTPUT); // Set the LED pin as output Serial.begin(9600); // Initialize serial communication } void loop() { int sensorState = digitalRead(floatSensorPin); // Read the sensor state if (sensorState == HIGH) { // Liquid level is below the threshold digitalWrite(ledPin, HIGH); // Turn on the LED Serial.println("Liquid level is low!"); } else { // Liquid level is above the threshold digitalWrite(ledPin, LOW); // Turn off the LED Serial.println("Liquid level is sufficient."); } delay(1000); // Wait for 1 second before reading again }

Important Considerations and Best Practices

- Ensure the float sensor is compatible with the liquid being monitored. Avoid using it with highly corrosive or viscous liquids.

- Mount the sensor securely in the tank or container to prevent movement or misalignment.

- Test the sensor in the intended environment to verify its functionality before full deployment.

- Use a pull-up or pull-down resistor if required, depending on the microcontroller and circuit design.

Troubleshooting and FAQs

Common Issues and Solutions

Sensor Not Responding:

- Cause: Loose or incorrect wiring.

- Solution: Double-check the connections and ensure the wires are securely attached.

False Triggering:

- Cause: Electrical noise or interference.

- Solution: Use a capacitor across the sensor terminals to filter noise.

Sensor Fails in Liquid:

- Cause: Incompatible liquid or damaged float.

- Solution: Verify the liquid compatibility and inspect the sensor for physical damage.

Microcontroller Not Detecting Sensor State:

- Cause: Incorrect pin configuration or faulty sensor.

- Solution: Ensure the microcontroller pin is configured as an input and test the sensor with a multimeter.

FAQs

Q1: Can the float sensor be used with AC voltage?

A1: No, the float sensor is designed for DC voltage only. Using it with AC voltage may damage the sensor.

Q2: How do I switch between Normally Open (NO) and Normally Closed (NC) modes?

A2: Some float sensors allow switching between NO and NC by inverting the float orientation. Refer to the specific sensor's datasheet for details.

Q3: Can the sensor detect multiple liquid levels?

A3: No, a single float sensor detects one liquid level. For multiple levels, use multiple sensors or a multi-level sensor.

Q4: Is the sensor waterproof?

A4: Yes, the sensor is designed to be waterproof and operate in liquid environments.

By following this documentation, users can effectively integrate the R.M ENTERPRISE float sensor (part ID SENSOR) into their projects for reliable liquid level monitoring.