How to Use 1407 3700kV motor: Examples, Pinouts, and Specs

Design with 1407 3700kV motor in Cirkit Designer

Design with 1407 3700kV motor in Cirkit DesignerIntroduction

The Cobra 1407 3700kV motor is a high-performance brushless DC motor designed for use in remote-controlled vehicles, drones, and other high-speed applications. With a 3700kV rating, this motor delivers 3700 revolutions per minute (RPM) per volt applied, making it ideal for applications requiring efficient power and speed. Its compact size and lightweight design make it particularly suitable for small to medium-sized drones and RC vehicles.

Explore Projects Built with 1407 3700kV motor

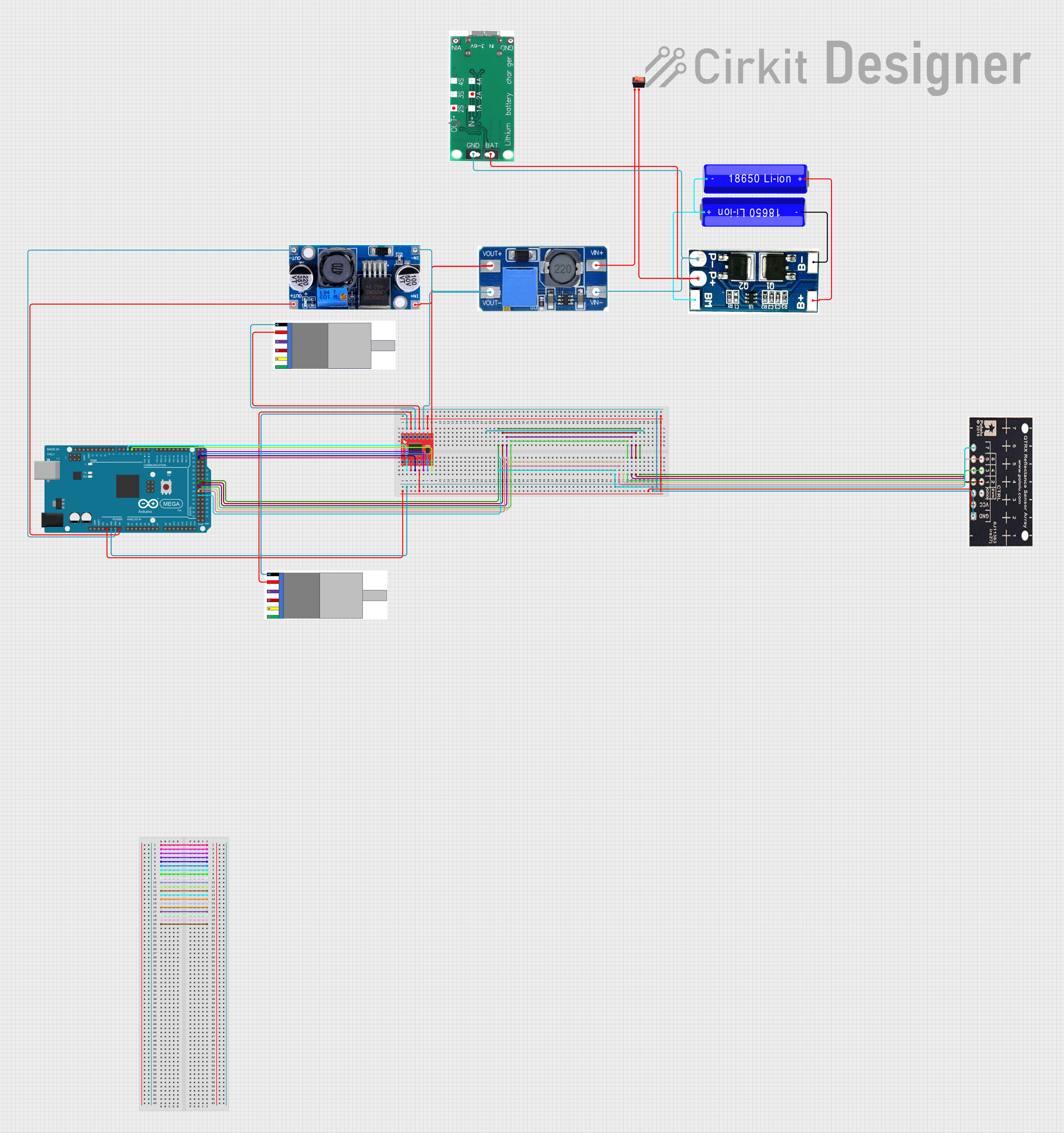

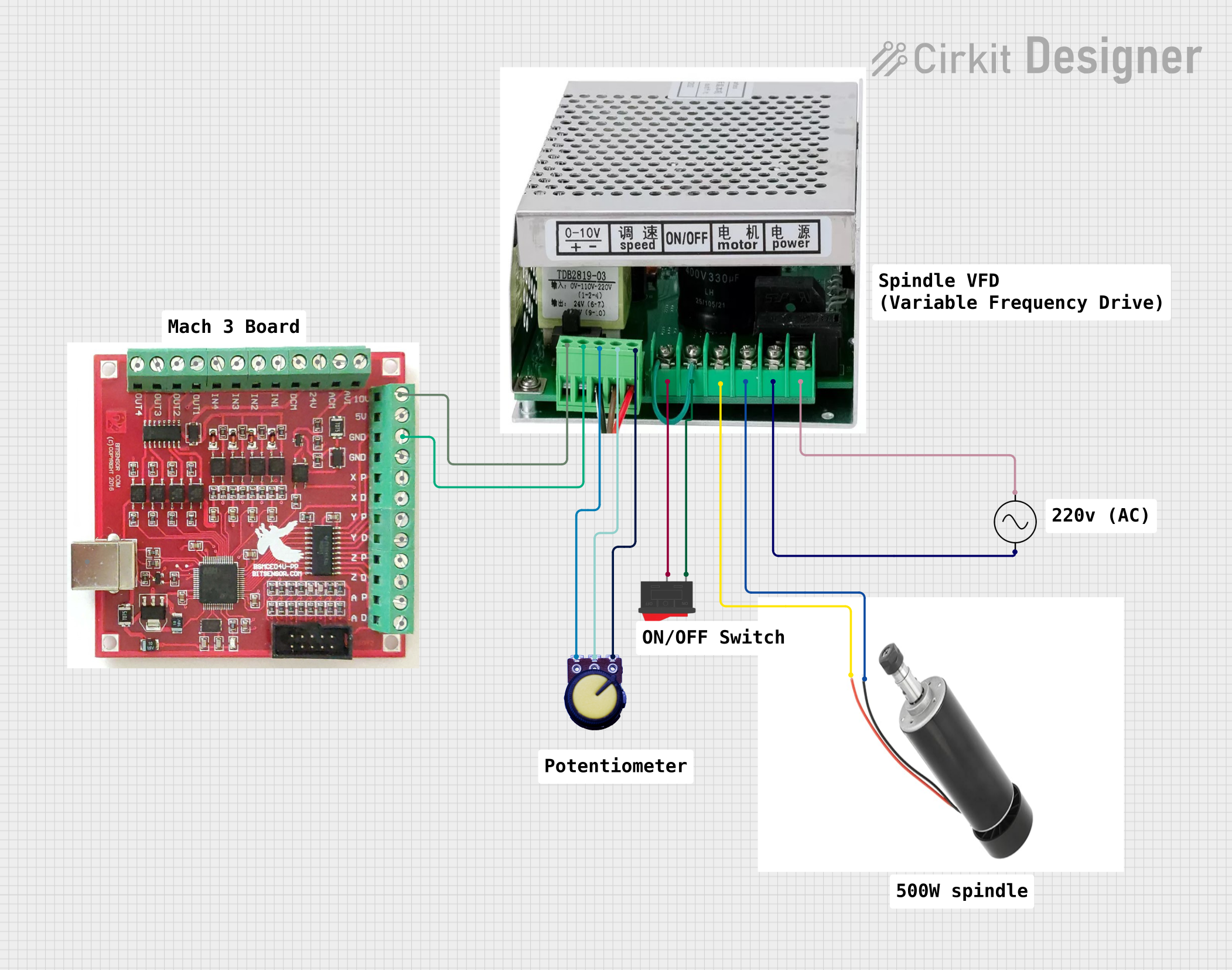

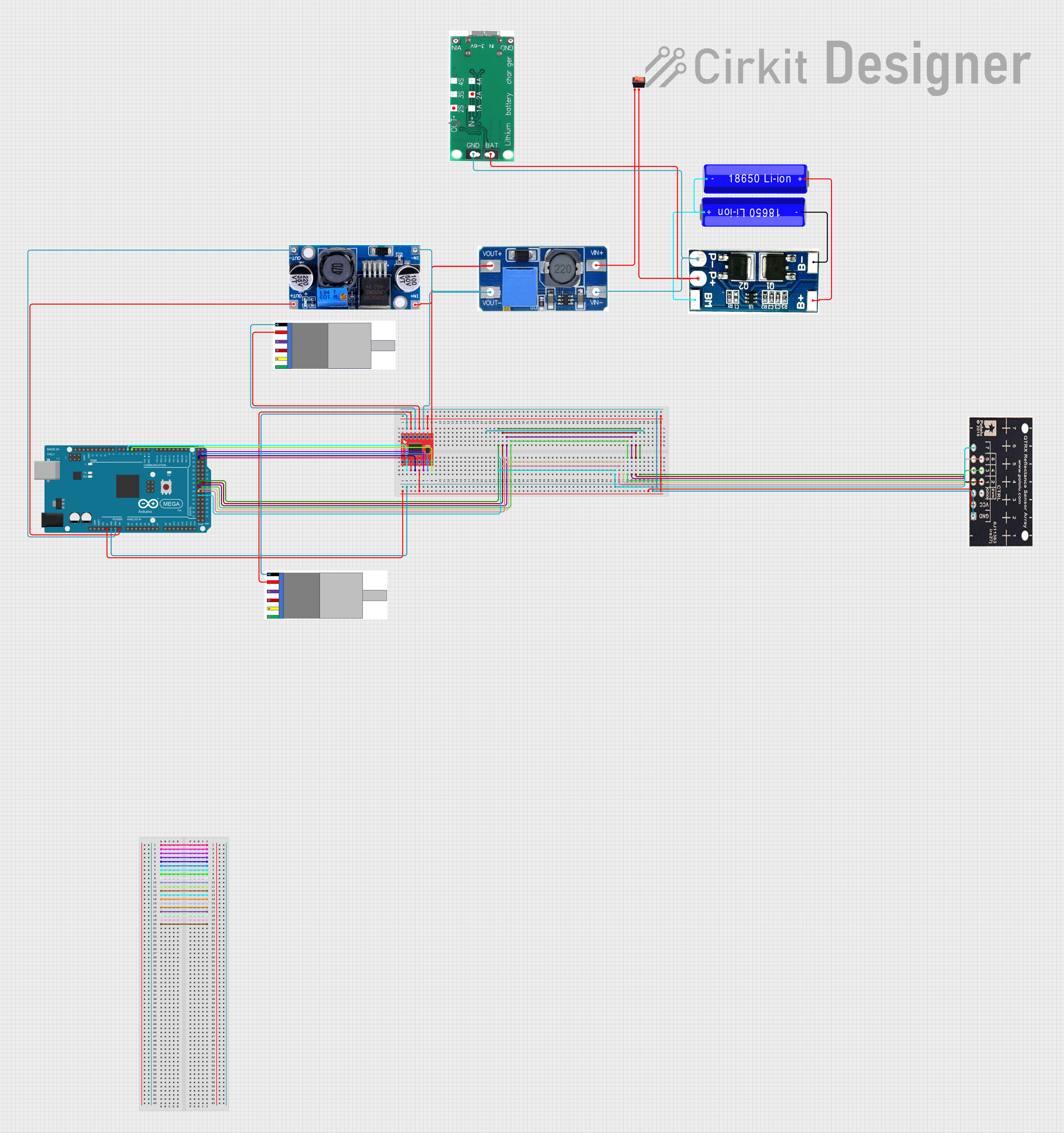

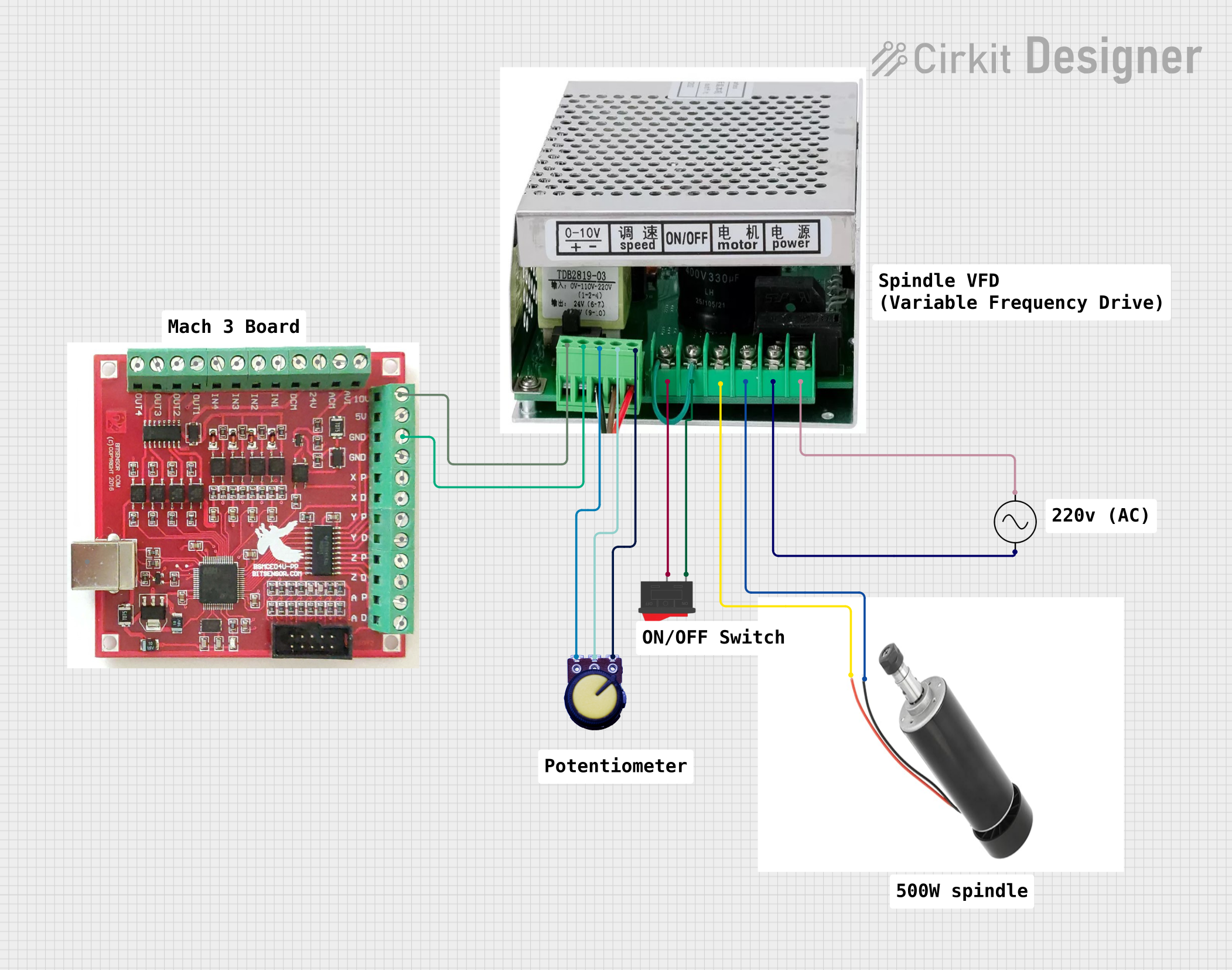

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 1407 3700kV motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Racing drones and quadcopters

- Remote-controlled cars and trucks

- Fixed-wing RC aircraft

- Robotics projects requiring high-speed motors

- DIY hobbyist projects

Technical Specifications

The following table outlines the key technical details of the Cobra 1407 3700kV motor:

| Specification | Value |

|---|---|

| Motor Type | Brushless DC (BLDC) |

| KV Rating | 3700 kV |

| Input Voltage Range | 2S-4S LiPo (7.4V - 14.8V) |

| Maximum Current | 12A |

| Maximum Power | 180W |

| Stator Dimensions | 14mm (diameter) x 7mm (height) |

| Shaft Diameter | 1.5mm |

| Weight | 15g |

| Mounting Hole Pattern | 12mm x 12mm |

| Recommended Propeller Size | 3" to 4" (depending on voltage) |

Pin Configuration and Descriptions

The Cobra 1407 3700kV motor has three wires for connection to an electronic speed controller (ESC). These wires are typically color-coded but may vary by manufacturer. The table below describes the connections:

| Wire Color | Function |

|---|---|

| Wire 1 | Phase A (connect to ESC output A) |

| Wire 2 | Phase B (connect to ESC output B) |

| Wire 3 | Phase C (connect to ESC output C) |

Note: The motor wires are not polarized, so the order of connection can be adjusted to change the motor's rotation direction.

Usage Instructions

How to Use the Motor in a Circuit

- Connect to an ESC: The motor must be connected to a compatible electronic speed controller (ESC) that supports brushless motors and the input voltage range (2S-4S LiPo).

- Power the ESC: Connect the ESC to a LiPo battery within the recommended voltage range (7.4V to 14.8V).

- Control the Motor: Use a radio transmitter and receiver or a microcontroller (e.g., Arduino) to send control signals to the ESC. The ESC will regulate the motor's speed and direction.

- Mount the Motor: Secure the motor to your drone or RC vehicle using the 12mm x 12mm mounting hole pattern. Attach a compatible propeller (3" to 4") to the motor shaft.

Important Considerations and Best Practices

- Cooling: Ensure proper airflow around the motor to prevent overheating during operation.

- Propeller Selection: Use a propeller size recommended for your voltage and application to avoid overloading the motor.

- ESC Compatibility: Use an ESC with a current rating higher than the motor's maximum current (12A) for safe operation.

- Direction Adjustment: If the motor spins in the wrong direction, swap any two of the three motor wires connected to the ESC.

Example: Using the Motor with an Arduino UNO

To control the motor with an Arduino UNO, you can use a compatible ESC and send PWM signals to adjust the motor speed. Below is an example code snippet:

#include <Servo.h> // Include the Servo library to control the ESC

Servo esc; // Create a Servo object to represent the ESC

void setup() {

esc.attach(9); // Connect the ESC signal wire to pin 9 on the Arduino

esc.writeMicroseconds(1000); // Send a minimum throttle signal to arm the ESC

delay(2000); // Wait for 2 seconds to ensure the ESC is armed

}

void loop() {

esc.writeMicroseconds(1500); // Set throttle to 50% (1500us is mid-throttle)

delay(5000); // Run the motor at 50% throttle for 5 seconds

esc.writeMicroseconds(1000); // Set throttle to 0% (stop the motor)

delay(5000); // Wait for 5 seconds before repeating

}

Note: Always remove the propeller when testing the motor to avoid accidents.

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin

- Cause: Incorrect wiring or ESC not armed.

- Solution: Verify the motor wires are connected to the ESC correctly. Ensure the ESC is receiving a valid signal from the controller or microcontroller.

Motor Spins in the Wrong Direction

- Cause: Incorrect phase wire connections.

- Solution: Swap any two of the three motor wires connected to the ESC.

Motor Overheats

- Cause: Overloading due to an oversized propeller or insufficient cooling.

- Solution: Use a smaller propeller or improve airflow around the motor.

ESC Beeps Continuously

- Cause: ESC is not receiving a valid signal or the battery voltage is too low.

- Solution: Check the signal connection between the ESC and the controller. Ensure the battery is charged and within the recommended voltage range.

FAQs

Q: Can I use this motor with a 5S or 6S LiPo battery?

A: No, the motor is rated for a maximum of 4S (14.8V). Using a higher voltage may damage the motor.Q: What is the best ESC for this motor?

A: Use an ESC with a current rating of at least 15A and support for 2S-4S LiPo batteries.Q: How do I mount the motor?

A: Use the 12mm x 12mm mounting hole pattern and screws compatible with your drone or RC vehicle frame.Q: Can I reverse the motor direction programmatically?

A: Yes, many ESCs allow you to reverse the motor direction via programming or transmitter settings.

By following this documentation, you can effectively integrate the Cobra 1407 3700kV motor into your projects and ensure optimal performance.